带锯CORMAK

HBS275

带锯

CORMAK

HBS275

固定价格 不包含增值稅

€1,349

製造年份

2025

狀況

全新

位置

Siedlce

顯示圖片

显示地图

价格和位置

固定价格 不包含增值稅

€1,349

- 位置:

- Brzeska 120, 08-110 Siedlce, Polska

撥打

优惠详情

- 產品ID:

- A16883691

- 最後更新:

- 於 07.01.2026

描述

CORMAK HBS275 band saw, equipped with a hydraulic cylinder, a cooling system and an arm swivelling up to 60º, together with blades from renowned German company Röntgen, is used commonly in ironworking, where precision, quality and cutting speed are essential.

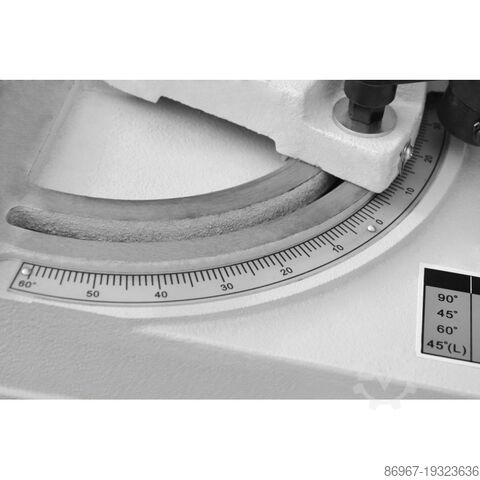

Horizontal band saw with a swivelling arm for cutting metals, allows for cutting in plane perpendicular to the axis of material cut and at any angle from 0 to 60º. Material for cutting can be fed manually or with any mechanical feeding device, with automatic tool feed. Band guides are equipped with dedicated carbide plates and bearings. This has a huge impact on band guiding, its durability, cut straightness, cutting accuracy and quality. Carbide guiding drastically reduces the wear of the machine and blades.

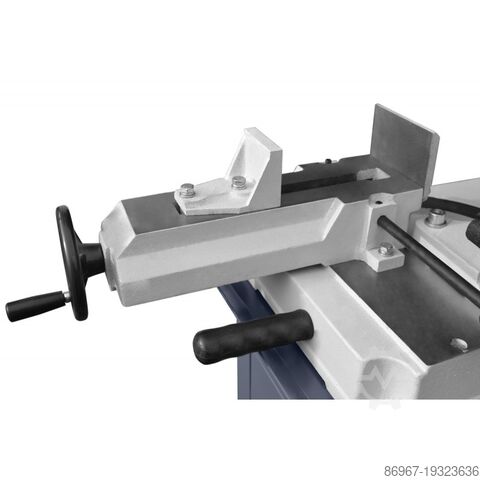

Machine's arm made of uniform cast iron as well as a 27 mm wide cutting band are capable of low and high quantity cutting of profiles and other materials. The vice is located in an adjustable bed, equipped with a quick clamp. Blade guides have cemented carbide plates and roller bearings. Its these cemented carbide guides that provide cut precision and straightness. The arm, positioned at an angle of 25º, thus increasing blade durability, is equipped with an automatic blade tension sensor. To the bottom of the arm a brush wire is attached, ensuring clean and functional brush. Machine's drive is transmitted through a worm drive. A 3-phase motor with 2 cutting speeds and motor thermal protection. This cutting machine also has a strain gauge - a band tension sensor and an automatic switch-off in case the cutting band breaks. Upper part of the base constitutes a tank for flood coolant draining and chips produced during cutting. A cast iron workbench is attached to the base, with a swivel arm and control panel on separate arm.

The main cutting move in the cutting process is moving the cutting band and the arm lowering feed. The arm lowering speed (the cutting speed) is adjusted with the hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds to choose from: 37.5 and 75 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Total power

1.5 kW

Power supply

400V 50Hz

Arm lowering control

hydraulic cylinder

Band dimensions

2455 x 27 x 0.9 mm

Band speed

37.5/75 m/min

Vice base height

900 mm

Weight

215 kg

Angle

0º

ø220

260 x 140

200 x 200

45º R

ø160

Kdsdpfx Ajudi Unjaxjg

160 x 140

160 x 160

60º R

ø100

120 x 100

100 x 100

Horizontal band saw with a swivelling arm for cutting metals, allows for cutting in plane perpendicular to the axis of material cut and at any angle from 0 to 60º. Material for cutting can be fed manually or with any mechanical feeding device, with automatic tool feed. Band guides are equipped with dedicated carbide plates and bearings. This has a huge impact on band guiding, its durability, cut straightness, cutting accuracy and quality. Carbide guiding drastically reduces the wear of the machine and blades.

Machine's arm made of uniform cast iron as well as a 27 mm wide cutting band are capable of low and high quantity cutting of profiles and other materials. The vice is located in an adjustable bed, equipped with a quick clamp. Blade guides have cemented carbide plates and roller bearings. Its these cemented carbide guides that provide cut precision and straightness. The arm, positioned at an angle of 25º, thus increasing blade durability, is equipped with an automatic blade tension sensor. To the bottom of the arm a brush wire is attached, ensuring clean and functional brush. Machine's drive is transmitted through a worm drive. A 3-phase motor with 2 cutting speeds and motor thermal protection. This cutting machine also has a strain gauge - a band tension sensor and an automatic switch-off in case the cutting band breaks. Upper part of the base constitutes a tank for flood coolant draining and chips produced during cutting. A cast iron workbench is attached to the base, with a swivel arm and control panel on separate arm.

The main cutting move in the cutting process is moving the cutting band and the arm lowering feed. The arm lowering speed (the cutting speed) is adjusted with the hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds to choose from: 37.5 and 75 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Total power

1.5 kW

Power supply

400V 50Hz

Arm lowering control

hydraulic cylinder

Band dimensions

2455 x 27 x 0.9 mm

Band speed

37.5/75 m/min

Vice base height

900 mm

Weight

215 kg

Angle

0º

ø220

260 x 140

200 x 200

45º R

ø160

Kdsdpfx Ajudi Unjaxjg

160 x 140

160 x 160

60º R

ø100

120 x 100

100 x 100

这些广告您可能也感兴趣。

小广告

Siedlce

Siedlce

6,436 km

带锯

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

小广告

德国

德国

7,100 km

中心车床和主轴车床

STRUNGURI ARADSN501x1500

STRUNGURI ARADSN501x1500

小广告

Schlüchtern

Schlüchtern

7,331 km

车床

Voest AlpineDA 160

Voest AlpineDA 160

小广告

Mindelheim

Mindelheim

7,389 km

带锯

MIOTAL®S 170 G

MIOTAL®S 170 G

小广告

Wien

Wien

6,997 km

焊接单元

FRONIUS TPS 5000 MIG MAG PULSTRANS PULS SYNERGIC 5000 / 500 MASCHINE

FRONIUS TPS 5000 MIG MAG PULSTRANS PULS SYNERGIC 5000 / 500 MASCHINE

小广告

Wiesbaden

Wiesbaden

7,429 km

柱钻

IXIONBSS-23 AV

IXIONBSS-23 AV

小广告

Böblingen

Böblingen

7,453 km

带锯

ZIMMERZ 241-1/R

ZIMMERZ 241-1/R

小广告

德国

德国

7,232 km

中心车床和主轴车床

PADOVANILABOR 230

PADOVANILABOR 230

小广告

Eislingen/Fils

Eislingen/Fils

7,406 km

截面受剪-联合

PEDDINGHAUS210/13

PEDDINGHAUS210/13

您的广告已成功删除

发生错误