覆膜机TPM

Katana 106 Laminiermaschine

覆膜机

TPM

Katana 106 Laminiermaschine

製造年份

2006

狀況

二手

位置

Neuhausen

顯示圖片

显示地图

机器数据

价格和位置

- 位置:

- 75242 Neuhausen-Schellbronn, Deutschland

撥打

优惠详情

- 產品ID:

- A20027830

- 最後更新:

- 於 19.09.2025

描述

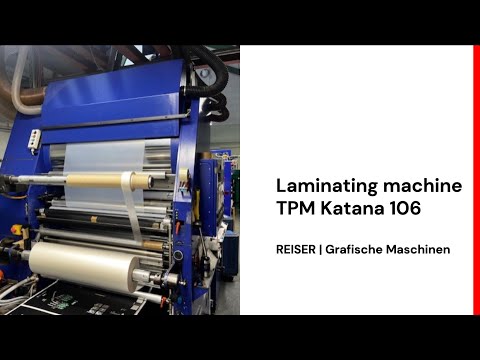

Laminating machine

TPM Katana 106

Duodpfxsxdhq Aj Ab Een

Year of manufacture 2006, approx. 36,000 operating hours

For thermal and wet lamination

Technical details and equipment:

Max. sheet format: 106 x 165 cm

Min. sheet format: 44 x 63 cm

Feeder: Mabeg

Extras: De-powdering and brushing device

Laminating unit with drying drum and separate laminating calender.

Large counterpressure roller for increased laminating pressure, 2-stage motor hydraulics

Hot water heated cylinders (2 separate temperature control devices)

2-stage air jet drying (separately controllable)

Sheet separator with flying knife (cross cutter) and short cut for OPP film

Stacker with sheet deformation and stop rollers

Central control and operation (Siemens control system / with Profibus)

The system has been regularly serviced by the manufacturer and is fully functional.

TPM Katana 106

Duodpfxsxdhq Aj Ab Een

Year of manufacture 2006, approx. 36,000 operating hours

For thermal and wet lamination

Technical details and equipment:

Max. sheet format: 106 x 165 cm

Min. sheet format: 44 x 63 cm

Feeder: Mabeg

Extras: De-powdering and brushing device

Laminating unit with drying drum and separate laminating calender.

Large counterpressure roller for increased laminating pressure, 2-stage motor hydraulics

Hot water heated cylinders (2 separate temperature control devices)

2-stage air jet drying (separately controllable)

Sheet separator with flying knife (cross cutter) and short cut for OPP film

Stacker with sheet deformation and stop rollers

Central control and operation (Siemens control system / with Profibus)

The system has been regularly serviced by the manufacturer and is fully functional.

这些广告您可能也感兴趣。

小广告

Warszawa

Warszawa

6,515 km

柔版标签印刷机

GidueI Combat

GidueI Combat

小广告

Płońsk

Płońsk

6,543 km

三刀修剪器

Wohlenberg38 FA

Wohlenberg38 FA

小广告

Helsinki

Helsinki

6,046 km

冲孔机

James BurnLhermite EX 610

James BurnLhermite EX 610

小广告

Wassenberg

Wassenberg

7,501 km

胶印机

KBARAPIDA 105U-4 + L

KBARAPIDA 105U-4 + L

小广告

София

София

6,743 km

胶印印刷机

HeidelbergSM 102 FP

HeidelbergSM 102 FP

小广告

Alsfeld

Alsfeld

7,328 km

折叠纸箱涂胶机

ANTER800

ANTER800

小广告

Kaunas

Kaunas

6,239 km

三刀修剪器

HorizonHT-101

HorizonHT-101

小广告

Helmstedt

Helmstedt

7,146 km

骑马订机

Mueller MartiniPrima Amrys

Mueller MartiniPrima Amrys

小广告

Velbert

Velbert

7,430 km

捆扎机

CyklopXZE-311

CyklopXZE-311

小广告

Bischofszell

Bischofszell

7,501 km

折叠机

MATHIAS BÄUERLEMULTIPLI 35 MIT GESTELL

MATHIAS BÄUERLEMULTIPLI 35 MIT GESTELL

您的广告已成功删除

发生错误