高速造粒机ZERMA

GST 250/600

高速造粒机

ZERMA

GST 250/600

起拍價 不包含增值稅

€19,400

製造年份

2025

狀況

全新

位置

Buchholz in der Nordheide

顯示圖片

显示地图

机器数据

价格和位置

起拍價 不包含增值稅

€19,400

- 位置:

- Vaenser Weg 12, 21244 Buchholz in der Nordheide, Deutschland

撥打

优惠详情

- 產品ID:

- A13548352

- 最後更新:

- 於 03.05.2025

描述

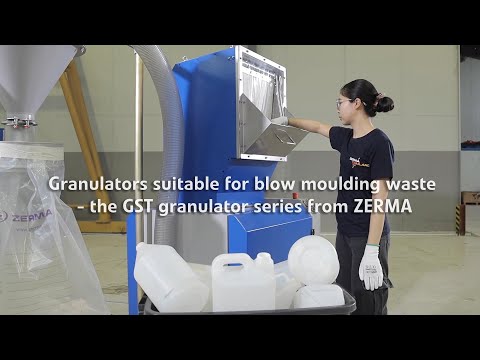

Size reduction of large-volume blow molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

Kjdsp Sr Iajpfx Aaxjdg

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive (kW) 11

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 1450

Feed opening (mm) 380 x 600

Feed opening option of M version (mm) 295 x 600

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

Kjdsp Sr Iajpfx Aaxjdg

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive (kW) 11

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 1450

Feed opening (mm) 380 x 600

Feed opening option of M version (mm) 295 x 600

廣告是自動翻譯的,翻譯中可能會出現一些錯誤。

这些广告您可能也感兴趣。

小广告

Dinkelscherben

Dinkelscherben

7,368 km

输送带输送带破碎机

die magnetprofis2019020502

die magnetprofis2019020502

小广告

Rimini

Rimini

7,457 km

竖向体块

VIROmod. TNG-4

VIROmod. TNG-4

小广告

Deitingen

Deitingen

7,622 km

工具磨床

W. ScherrerSB 10

W. ScherrerSB 10

小广告

Wasbek

Wasbek

7,121 km

立柱式钻床 - SSB F 60 Super VT PRO

KnuthSSB F 60 Super VT PRO

KnuthSSB F 60 Super VT PRO

小广告

Dortmund

Dortmund

7,394 km

折弯机

LAMI NOVAP 1340

LAMI NOVAP 1340

小广告

Mindelheim

Mindelheim

7,389 km

双斜接带锯

MIOTALS 255 DG

MIOTALS 255 DG

小广告

Berlin

Berlin

6,990 km

小货车

PEUGEOTBoxer Euro 5 3,80m

PEUGEOTBoxer Euro 5 3,80m

小广告

Zuzenhausen

Zuzenhausen

7,431 km

碎纸机

ZERMAZRS

ZERMAZRS

小广告

Velbert

Velbert

7,430 km

捆扎机

CyklopXZE-311

CyklopXZE-311

小广告

Sinsheim

Sinsheim

7,429 km

造粒机

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

您的广告已成功删除

发生错误