水、油、肥皂、AdBlue 灌装机PROTON EE-ELEKTRONIKA d.o.o

XFR1000

水、油、肥皂、AdBlue 灌装机

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

製造年份

2025

狀況

全新

位置

Šašinovec

顯示圖片

显示地图

机器数据

价格和位置

- 位置:

- Krcevina 4, 10360 Soblinec, Hrvatska

撥打

技术细节

- 总宽度:

- 2,400 毫米

- 总长度:

- 15,000 毫米

- 总高度:

- 2,800 毫米

- 压力:

- 8 横杆

- 功率:

- 10.9 千瓦 (14.82 马力)

- 空载重量:

- 6,400 千克

- 输入电压:

- 400 V

- 充填重量(最小):

- 200 g

- 填充重量(最大):

- 5,000 g

优惠详情

- 產品ID:

- A17231422

- 最後更新:

- 於 25.09.2025

描述

XFR 1000

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

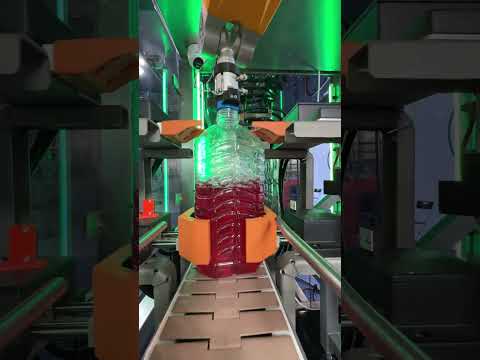

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

Bedpeuq Nv Tsfx Ad Iscw

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

Bedpeuq Nv Tsfx Ad Iscw

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

这些广告您可能也感兴趣。

小广告

德国

德国

7,232 km

制袋机

Honsel & Co.722

Honsel & Co.722

小广告

德国

德国

7,232 km

面条机

JuwelPQ6-SU/PQ3-SU

JuwelPQ6-SU/PQ3-SU

小广告

Jüri

Jüri

6,067 km

卸货机

Valon Kone OYVK-550-Combi 2R/480(620)

Valon Kone OYVK-550-Combi 2R/480(620)

小广告

Ostrołęka

Ostrołęka

6,447 km

奶及奶制品生产

MargoPasteryzator

MargoPasteryzator

小广告

Breda

Breda

7,552 km

WEBER DS 8.5 PVC 管道最长 160 毫米

WeberWEBER DS 8.5

WeberWEBER DS 8.5

小广告

Ieriķi

Ieriķi

6,103 km

托盘生产机

FORMAPBS M4

FORMAPBS M4

小广告

Sevenum

Sevenum

7,489 km

在线脉冲填充器

KingKT340/ILKT

KingKT340/ILKT

小广告

Bad Lippspringe

Bad Lippspringe

7,302 km

烤箱

GRILLOMAX GRILLSTATIONGRILLSTATION

GRILLOMAX GRILLSTATIONGRILLSTATION

小广告

Thamsbrück

Thamsbrück

7,222 km

栓剂灌装封口厂

CP-Citopac Technology and Packaging GmbHFKS-10

CP-Citopac Technology and Packaging GmbHFKS-10

小广告

Lagedi

Lagedi

6,064 km

压榨容器

HusmannSPB 20 SEN-E

HusmannSPB 20 SEN-E

您的广告已成功删除

发生错误